Deflashers

Questions?

Trinks Inc. Deflashing Systems function with high efficiency in integrated manufacturing cells. Similar parts or families of parts are molded and finished within the stringent quality and time constraints of just-in-time manufacturing.

Small-footprint units are compactly designed to operate near molding presses. They can be easily configured for automatic or semi-automatic operation to eliminate hand finishing and increase production throughput.

Low Pro Inline

The Low-Pro Deflashing System is ideally suited for working in tandem with your molding process and can accommodate manual or automated feeding. With a simple process, the system conveyor moves parts through two steps, blasting and cleaning. The chambered design isolates each process by eliminating cross contamination.

- Up to sixteen (16) blast guns. Nozzles are mounted on universal swing arms for easy adjustment and greater effectiveness

- Durable ceramic blast nozzles

- One piece design unit w/blast chamber, cyclone separator, media feed system & all electrical

pneumatic controls - Double belt conveyor system

- PLC with operator interface and push buttons

- Internal baffling

- Explosion-proof light

- Anti-static humidifier

- Full opening/removable access door

- Flash trap screen floor w/vibrator

- Mounted exit cleaning/blow-off station

- NRTL Certifications: UL, CUL, CSA, or CE Mark

- Additional blast units

- Gun clog sensor

- Low level media sensor

- Low pressure sensor alarm

Rollaveyor

The Rollaveyor Deflashing system provides automated, high efficiency deflashing at your molding press for small or large parts, in batch, or continuous operation. Small parts may be deflashed individually or in twin blast chambers. Dividers may be added to create up to eight compartments with separate tumbling paths.

- Up to sixteen (8) blast guns mounted on an oscillating gun bracket for greater effectiveness

- Freestanding dust collector with automatic filter shaker and quick release dust pail

- Automatic media refill hopper for steady flow

- Size-interchangeable durable nozzles

- Explosion-proof lights

- Air intake humidifer to reduce dust and static

- Anti-static blow off system to assist removal of dust

- Full opening access door

- NRTL Certifications: UL, CUL, CSA, or CE Mark

- Additional blast units

- Gun clog sensor

- Low level media sensor

- Low pressure sensor alarm

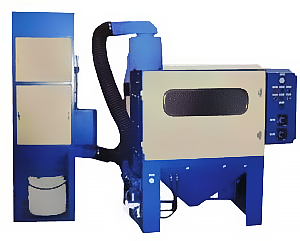

Tumble Blast

The semi-automatic tumble blast deflashers are specifically engineered for tumble blast cleaning large volumes of small parts. Each unit features a compact modular system that includes a cyclone media separator, dust collector and a coated basket containing (2) guns to pneumatically blast parts with media for positive deflashing and less staining.

- Up to sixteen (2) blast guns mounted on an oscillating gun bracket for greater effectiveness

- Freestanding dust collector with automatic filter shaker and quick release dust pail

- Automatic media refill hopper for steady flow

- Size-interchangeable durable nozzles

- Explosion-proof lights

- Air intake humidifer to reduce dust and static

- Anti-static blow off system to assist removal of dust

- Full opening access door

- NRTL Certifications: UL, CUL, CSA, or CE Mark

- Additional blast units

- Gun clog sensor

- Low level media sensor

- Low pressure sensor alarm