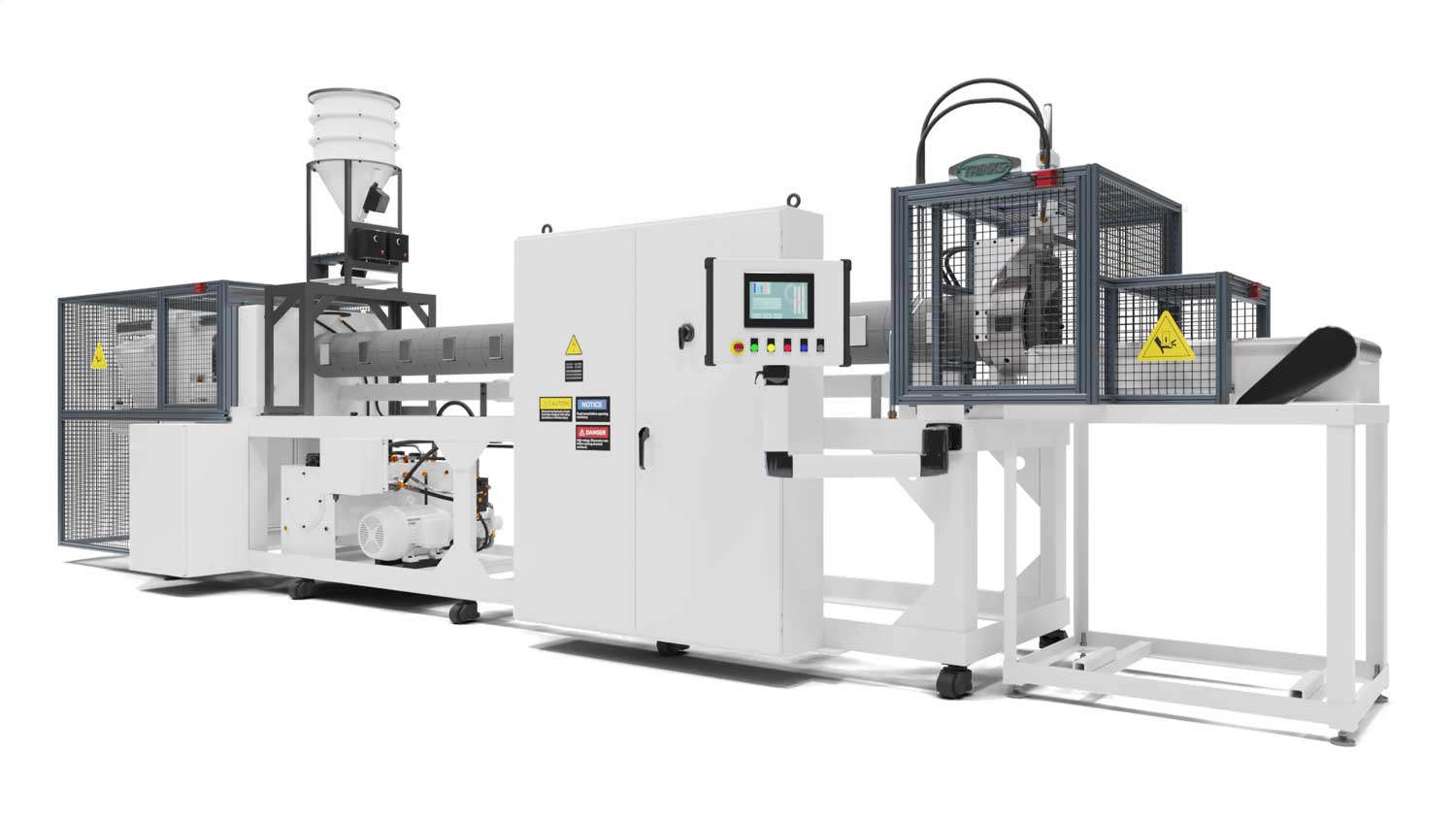

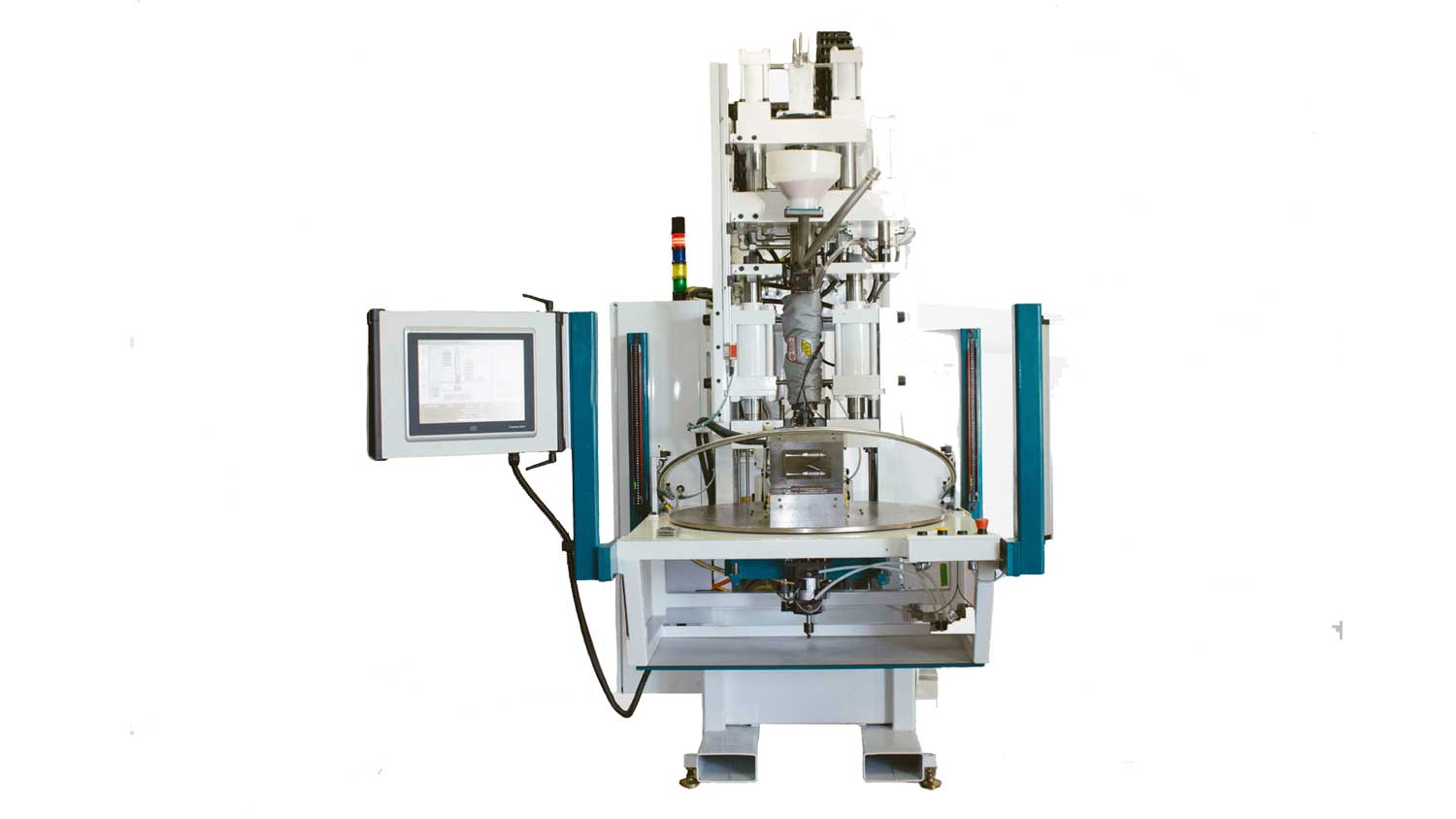

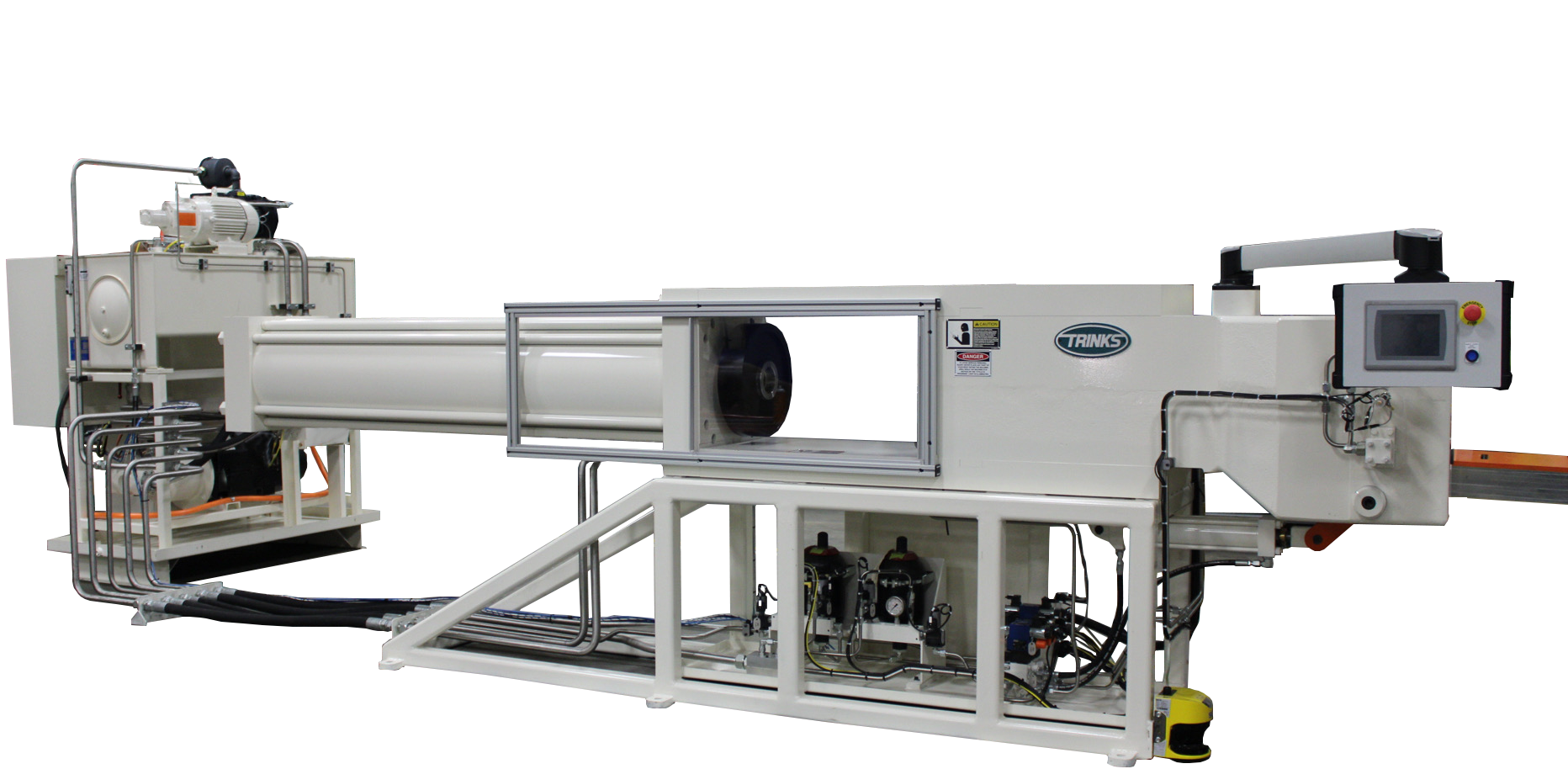

Your Process. Our Expertise. Built For Performance.

From concept to completion, Trinks Inc. engineers custom and standard press systems tailored to your production goals. Browse our featured press categories to find the right fit for your operation.

What Sets Us Apart

At Trinks Inc., we’ve spent nearly a century helping manufacturers press forward with confidence. Here’s why industry leaders across the globe trust us with their most demanding applications:

Custom Solutions: Built to your exact needs—standard or fully engineered.

Engineering Expertise: Decades of innovation in every machine.

Integrated Systems: Turnkey automation and control beyond the press.

Global Support: Fast, reliable service—wherever you are.

- Proven Performance: Durable, precise, and consistent.

INDUSTRIES We Serve

Trinks Inc. delivers performance-driven press solutions to industries that demand precision, durability, and innovation. While we support a wide range of sectors, these five remain our most trusted and time-tested partnerships.

Automotive

Presses for components, interiors, and structural parts.

Medical

Precision solutions meeting strict regulatory requirements.

Defense

Built for high-stakes, mission-critical applications.

Aerospace

Built for high-stakes, mission-critical applications.

Marine

Corrosion-resistant systems tailored to marine applications.

Don’t see your industry? We engineer custom press systems for niche and emerging markets. LET’S BUILD YOURS.