Service & Support

Maintenance is essential to keeping hydraulic and electric press systems operating safely, efficiently, and without interruption. To support continuous production, Trinks Inc. provides responsive assistance, certified expertise, and reliable solutions that keep equipment performing at its best.

Explore Our Support

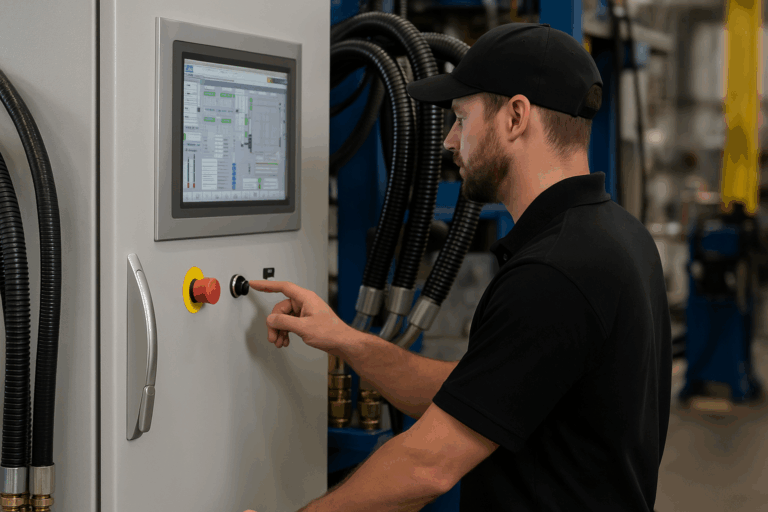

Following installation, Trinks Inc. technicians assist with the initial machine startup. During this process, key settings are calibrated, safety functions are verified, and cycle operation is confirmed. As a result, the equipment integrates smoothly into the production environment and begins operating reliably from day one.

When a press goes down, Trinks Inc. technicians respond quickly to diagnose the issue, correct the fault, and restore full functionality. In addition, fast troubleshooting helps reduce downtime, and consequently, production returns to normal operation much sooner.

Retrofit solutions modernize existing equipment while preserving the core design. Additionally, Trinks Inc. provides hardware upgrades, software enhancements, and integrated improvements that increase accuracy, efficiency, and long-term reliability. As a result, older machines continue performing at today’s production standards.

Preventative maintenance identifies wear early, improves cycle consistency, and reduces the risk of unexpected downtime. Furthermore, Trinks Inc. technicians inspect key components, verify system performance, and make adjustments that support safe and efficient operation. Consequently, equipment stays reliable for longer periods.

Program updates enhance system performance by improving PLC logic, interfaces, alarms, and process controls. When supported, updates can be installed remotely; however, more complex requirements may require on-site installation. In either case, upgraded software helps the press operate more consistently and efficiently.

Trinks Inc. supplies a wide range of replacement parts and custom parts packages designed for each machine’s specific requirements. In addition, technicians evaluate component needs, recommend appropriate replacements, and support continued performance and long-term reliability. As a result, systems remain stable and productive.

Trinks Inc. technicians perform on-site evaluations to review machine condition, safety, and performance. During the assessment, real-time adjustments can be made to improve efficiency, and afterward, technicians provide recommendations for upgrades or retrofits. Consequently, operators gain a clearer understanding of system needs and improvement opportunities.

Expert Technicians

Minimized Downtime

Long-Term Partnership