What We Do

Applications

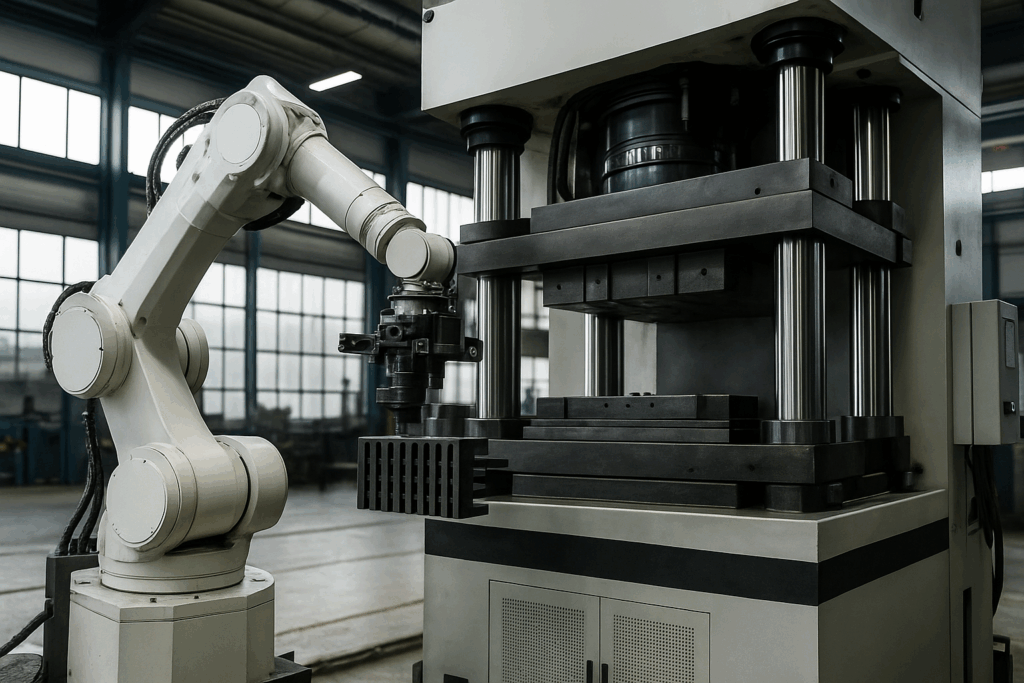

Applications in modern manufacturing require accuracy, repeatability, and reliable material handling. Trinks Inc. supports a wide range of production needs—including deflashing, mold cleaning, quick mold mounting, robot integration, and vision inspection. As a result, these specialized solutions help improve consistency, streamline workflows, and support safer, more efficient operations.

Press Solutions We Support

Trinks Inc. offers a variety of press-focused solutions designed for compression, transfer, and vacuum molding environments. Additionally, these systems reduce manual handling, stabilize cycle times, and improve molded-part consistency. In addition, each setup aligns with specific material and temperature needs to maintain predictable results.

Molded-Part Production Solutions

For molded components, Trinks provides deflashing stations, mold-cleaning equipment, and quick mold-mounting tools. For example, these reliable systems help remove excess material, prepare molds efficiently, and reduce setup time. Furthermore, each solution supports safer operation and long-term durability in high-demand environments.

Automation for Part Handling

Automation plays a vital role in improving productivity and accuracy. Trinks Inc. integrates robotics, insert loading, vision tools, and end-of-line handling systems to support smoother production flow. Consequently, manufacturing teams experience shorter cycle times, better quality checks, and fewer manual steps.

Below are examples of the automation and manufacturing applications Trinks Inc. supports:

- Robot integration

- Post-mold degating stations

- Mold material loading

- Insert loading

Vision inspection

- Offloading and material flow

- Mold cleaning

- Deflashing Systems

- Quick mold mounting

Learn more about industry standards at the Plastics Industry Association: https://www.plasticsindustry.org/